Description

PLASMA CUTTING MACHINE MODEL TM80i / TM100i / TM120i

- High cutting speed: Compared to the conventional type, our dual tips design can increase the cutting speed.

- Less consumable: While cutting thick plates, the inner tip is completely protect, which makes a safer operation.

- The machine is operated with 40% of power saving and less noise.

- The output current is set and displayed in digital format.

- Special dual tips design: Thin plates can be cut with the single tip for smaller kerfs, and thick plates can be cut with dual tips for a better quallity result.

- The mechine is worked in 100% of duty cycle, and is compatible with CNC system and other automatic equipments.

- The machine is covered under a complete protection, which includes the trouble detections for gas pressure, machine’s temperature, input voltage, over current, short-circuited electrode, and ignition failure.

- Designed with the gouging function.

- 100% of compressed air is flowing through both of the inner and outer tips, which result in the best cooling effect and the extended usage life of the torch.

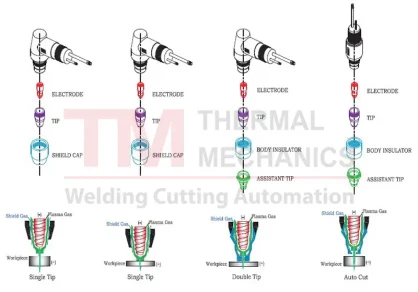

Torch Application

Operating Data

| Material | Current (amps) | Thickness (mm) | Max Travel Speed (mm/min) |

|---|---|---|---|

| Mind Steel | 120A | 6 | 5280 |

| 9 | 2700 | ||

| 16 | 1450 | ||

| 100A | 4.5 | 4800 | |

| 9 | 2400 | ||

| 16 | 1250 | ||

| 80A | 3 | 5400 | |

| 9 | 1900 | ||

| 12 | 1400 | ||

| Stainlees Steel | 120A | 6 | 3700 |

| 9 | 2400 | ||

| 16 | 1050 | ||

| 100A | 4.5 | 4600 | |

| 9 | 2100 | ||

| 16 | 900 | ||

| 80A | 3 | 4800 | |

| 9 | 2800 | ||

| 12 | 1100 | ||

| Aluminum | 120A | 6 | 4000 |

| 9 | 2400 | ||

| 16 | 1000 | ||

| 100A | 4.5 | 4000 | |

| 9 | 2100 | ||

| 16 | 900 | ||

| 80A | 3 | 1800 | |

| 9 | 1600 | ||

| 12 | 1100 |

Specification

Chopper System

120A Recommended Capacity: 28mm Pierce: 22mm Severance Capacity: 55mm

| Model | TM-120D |

|---|---|

| Input Voltage | 3 Phase 380V. 50Hz. |

| Output Current | 30-120A |

| Input Power | 24 KVA |

| Duty Cycle | 100%(@40%C) |

| Pilot Arc | With |

| Size (LxWxH) | 810 x 480 x 780 mm |

| Weight (kg) | 170 kg |

Chopper System

100A Recommended Capacity: 25mm Pierce: 15mm Severance Capacity: 40mm

| Model | TM-100D |

|---|---|

| Input Voltage | 3 Phase 380V. 50Hz. |

| Output Current | 30-120A |

| Input Power | 16.5 KVA |

| Duty Cycle | 100%(@40%C) |

| Pilot Arc | With |

| Size (LxWxH) | 530 x 360 x 655 mm |

| Weight (kg) | 165 kg |

Inverter System

80A Recommended Capacity: 20mm Pierce: 15mm Severance Capacity: 40mm

| Model | TM-80D |

|---|---|

| Input Voltage | 3 Phase 380V. 50Hz. |

| Output Current | 20-60A |

| Input Power | 13.5 KVA |

| Duty Cycle | 100%(@40%C) |

| Pilot Arc | With |

| Size (LxWxH) | 530 x 360 x 655 mm |

| Weight (kg) | 65 kg |

- Description

-

PLASMA CUTTING MACHINE MODEL TM80i / TM100i / TM120i

- High cutting speed: Compared to the conventional type, our dual tips design can increase the cutting speed.

- Less consumable: While cutting thick plates, the inner tip is completely protect, which makes a safer operation.

- The machine is operated with 40% of power saving and less noise.

- The output current is set and displayed in digital format.

- Special dual tips design: Thin plates can be cut with the single tip for smaller kerfs, and thick plates can be cut with dual tips for a better quallity result.

- The mechine is worked in 100% of duty cycle, and is compatible with CNC system and other automatic equipments.

- The machine is covered under a complete protection, which includes the trouble detections for gas pressure, machine’s temperature, input voltage, over current, short-circuited electrode, and ignition failure.

- Designed with the gouging function.

- 100% of compressed air is flowing through both of the inner and outer tips, which result in the best cooling effect and the extended usage life of the torch.

Torch Application

Operating Data

Material Current (amps) Thickness (mm) Max Travel Speed

(mm/min)Mind Steel 120A 6 5280 9 2700 16 1450 100A 4.5 4800 9 2400 16 1250 80A 3 5400 9 1900 12 1400 Stainlees Steel 120A 6 3700 9 2400 16 1050 100A 4.5 4600 9 2100 16 900 80A 3 4800 9 2800 12 1100 Aluminum 120A 6 4000 9 2400 16 1000 100A 4.5 4000 9 2100 16 900 80A 3 1800 9 1600 12 1100 Specification

Chopper System

120A Recommended Capacity: 28mm Pierce: 22mm Severance Capacity: 55mm

Model TM-120D Input Voltage 3 Phase 380V. 50Hz. Output Current 30-120A Input Power 24 KVA Duty Cycle 100%(@40%C) Pilot Arc With Size (LxWxH) 810 x 480 x 780 mm Weight (kg) 170 kg Chopper System

100A Recommended Capacity: 25mm Pierce: 15mm Severance Capacity: 40mm

Model TM-100D Input Voltage 3 Phase 380V. 50Hz. Output Current 30-120A Input Power 16.5 KVA Duty Cycle 100%(@40%C) Pilot Arc With Size (LxWxH) 530 x 360 x 655 mm Weight (kg) 165 kg Inverter System

80A Recommended Capacity: 20mm Pierce: 15mm Severance Capacity: 40mm

Model TM-80D Input Voltage 3 Phase 380V. 50Hz. Output Current 20-60A Input Power 13.5 KVA Duty Cycle 100%(@40%C) Pilot Arc With Size (LxWxH) 530 x 360 x 655 mm Weight (kg) 65 kg - Gallery

-

- Video

-